As a low-to-medium volume supplier serving a variety of industries, we provide quick responses to your needs, ensuring your production stays on track.

handling raw part cross-section sizes of up to 320 x 200 mm (12” x 8”) and lengths of 7.6 m (25 ft). We deliver fully machined parts in a single pass, with finished lengths ranging from 0.3 to 7.6 m (1–25 ft), all within a climate-controlled environment. Our precision machining ensures tolerances of less than 0.12 mm (0.005”).

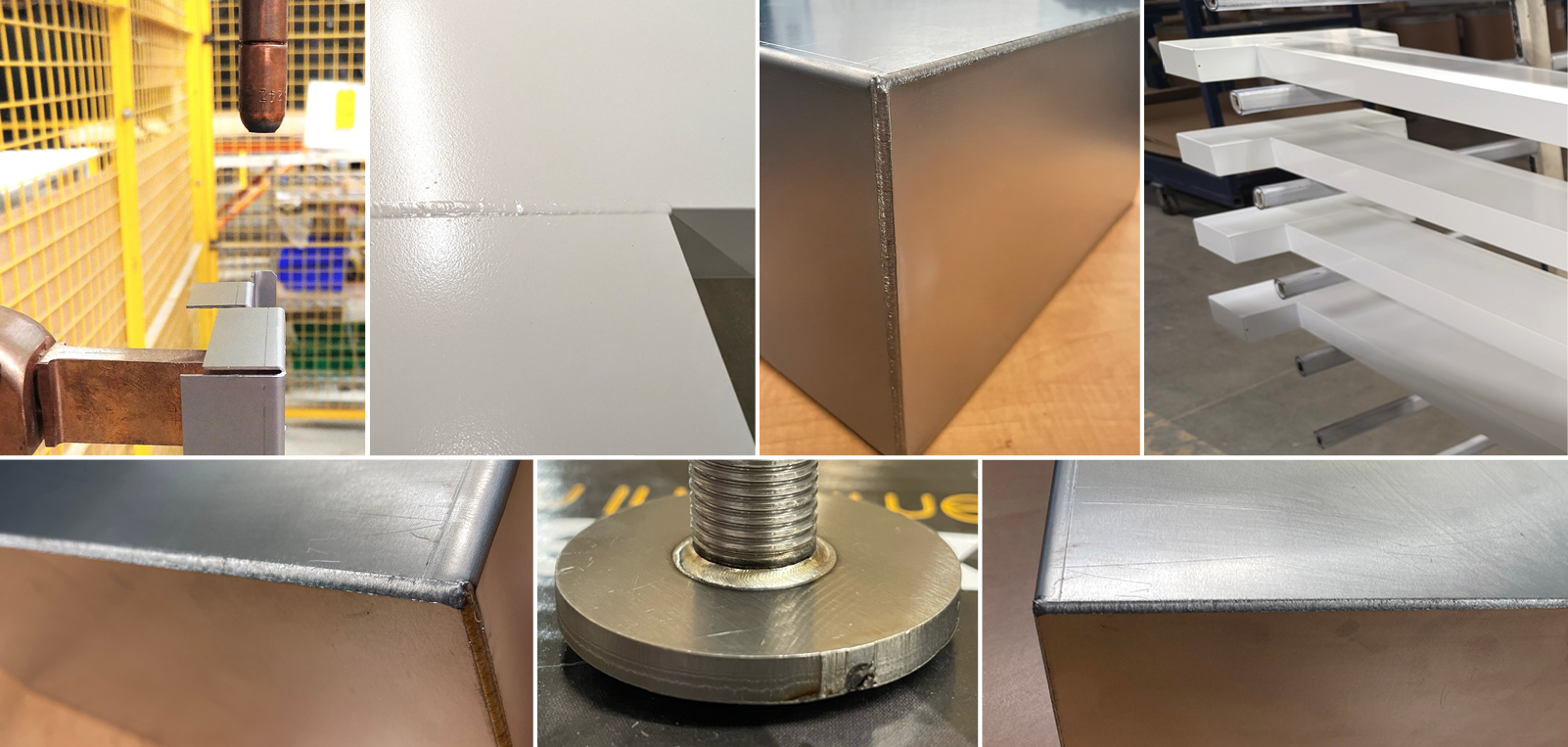

We specialize in steel, stainless steel, and aluminum, offering shearing, punching, laser coil processing, and braking for parts up to 3.7 m (12 ft) in length and 3.0 mm (1/8 in.) in thickness.

Lead times range from 1–2 weeks, depending on part complexity, with scalable capacity to meet your needs.

Robotic Spot Welding: Ideal for light-gauge products.

Laser Welding: Delivers robust and aesthetically pleasing finishes for materials ranging from 0.9 mm (0.036 in.) to 6 mm (1/4 in.).

We offer IP65-rated automated silicone gasketing using advanced 5-axis robots. Our system handles parts up to 3.7 m (12 ft) with a maximum table surface area of 600 x 3,700 mm (2 x 12 ft). Gasket dimensions can be optimized to suit your application, with a maximum width of 12 mm (0.5 in.) and height of 5 mm (0.25 in.).

Our powder coat painting process meets AAMA 2605 standards, ensuring over 2,000 hours of salt spray corrosion resistance. Using a robotic powder paint booth and infrared bake oven, we achieve consistent, high-quality finishes on parts up to 7.5 m (25 ft) in length, with cross-sections up to 1 x 1.2 m (3 x 4 ft).

Pre-Paint Services: Masking, plugging, and sub-assembly preparation are available to ensure components are ready for coating.

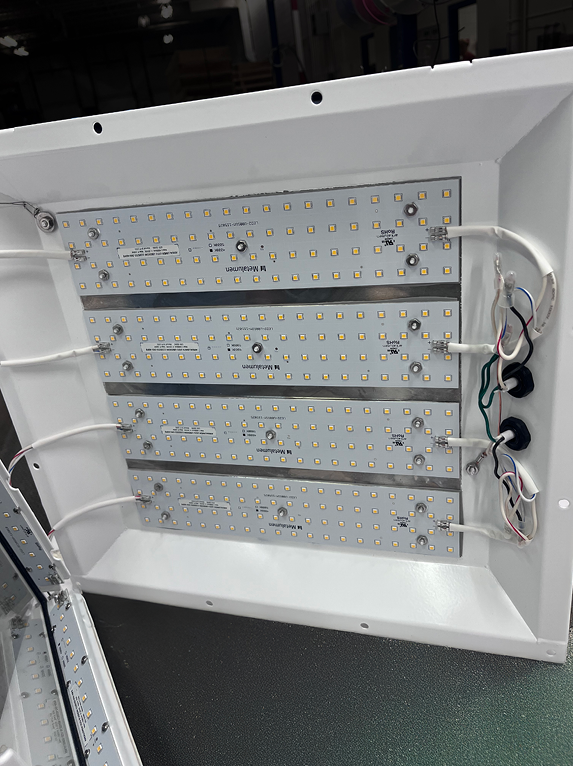

We offer complete electrical and mechanical assembly services, including component integration and testing after painting and finishing. This streamlines your production process by reducing hand-offs and ensuring that fully finished assemblies are delivered ready for installation or final deployment.

UL/CSA Certified Electrical Installation and Testing: Integration and testing of electrical components as required.

ISO-Based Quality System: Ensures parts meet specifications the first time through.

Material Handling: Equipped with cranes and forklifts for seamless internal handling and truck loading/unloading.