Precision Metal Fabrication, Assembly & Finishing

Keeping your production on schedule with on‑time, contract-ready delivery from engineered aluminum and metal system experts

At Metalumen, we specialize in supporting manufacturers with ongoing, scalable subcontracting solutions.

Whether you’re facing a production bottleneck or looking to offload complex assemblies, we’re here to help you stay on track–and grow.

What We Offer

At Metalumen, our exceptional expertise lies in

Aluminum Extrusion Machining

Handling raw part cross-section sizes of up to 320 x 200 mm (12” x 8”) and lengths of 7.6 m (25 ft), we deliver fully machined parts in a single pass, with finished lengths ranging from 0.3 to 7.6 m (1–25 ft), all within a climate-controlled environment. Our precision machining ensures tolerances of less than 0.12 mm (0.005”).

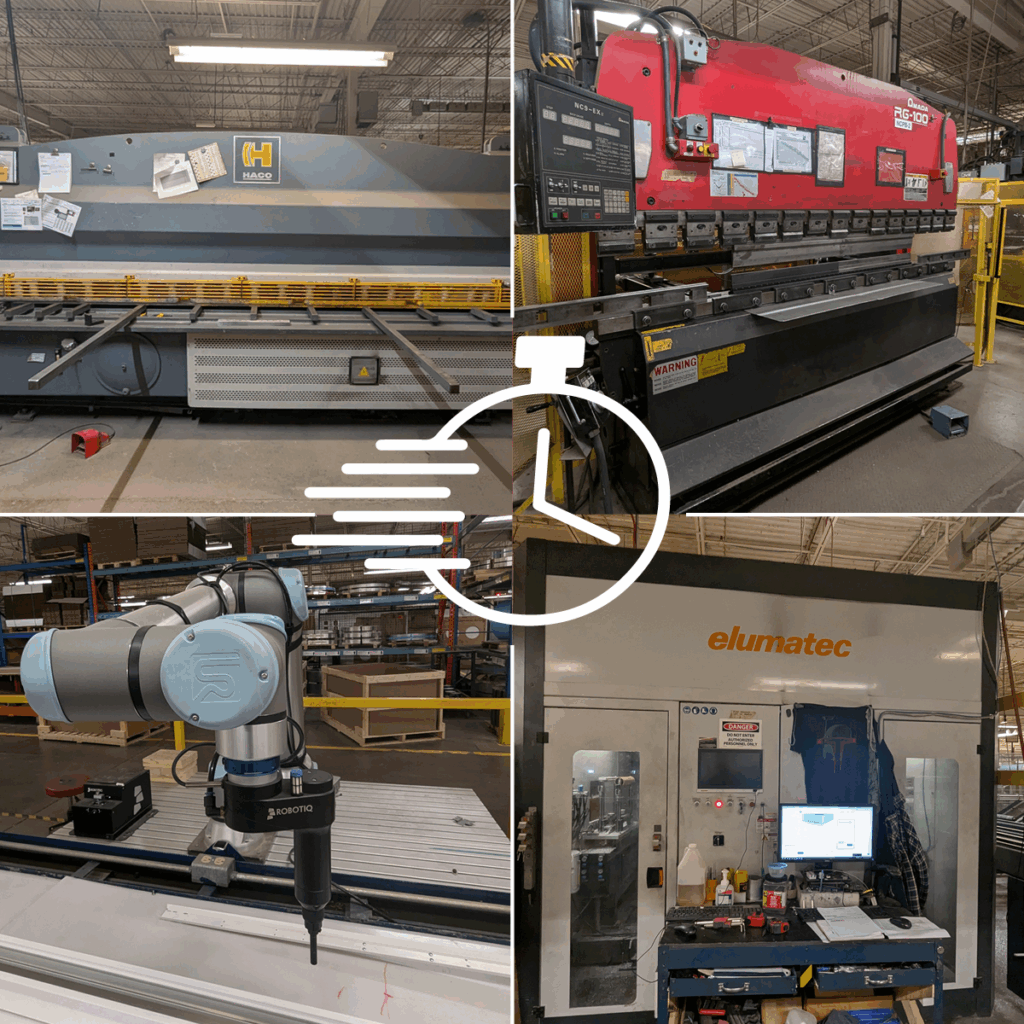

Scalable and Quick Fabrication Solutions

Sheet Metal Processing

We specialize in steel, stainless steel, and aluminum, offering shearing, punching, laser coil processing, and braking for parts up to 3.7 m (12 ft) in length and 3.0 mm (1/8 in.) in thickness.

Fast Production Times

Lead times range from 1–2 weeks, depending on part complexity, with scalable capacity to meet your needs.

Advanced Welding Capabilities

Robotic Spot Welding: Ideal for light-gauge products.

Laser Welding: Delivers robust and aesthetically pleasing finishes for materials ranging from 0.9 mm (0.036 in.) to 6 mm (1/4 in.).

Automated Silicone Gasketing

We offer IP65-rated automated silicone gasketing using advanced 5-axis robots. Our system handles parts up to 3.7 m (12 ft) with a maximum table surface area of 600 x 3,700 mm (2 x 12 ft). Gasket dimensions can be optimized to suit your application, with a maximum width of 12 mm (0.5 in.) and height of 5 mm (0.25 in.).

Powder Coat Painting

Our powder coat painting process meets AAMA 2605 standards, ensuring over 2,000 hours of salt spray corrosion resistance. Using a robotic powder paint booth and infrared bake oven, we achieve consistent, high-quality finishes on parts up to 7.5 m (25 ft) in length, with cross-sections up to 1 x 1.2 m (3 x 4 ft).

Pre-Paint Services: Masking, plugging, and sub-assembly preparation are available to ensure components are ready for coating.

Electrical and Mechanical Assembly

We offer complete electrical and mechanical assembly services, including component integration and testing after painting and finishing. This streamlines your production process by reducing hand-offs and ensuring that fully finished assemblies are delivered ready for installation or final deployment.

Why Choose Metalumen?

Fast Lead Times

1–2 weeks depending on complexity

Scalable Capacity

Ready to grow with your needs

Quality Assurance and Certification

ISO-based processes and UL/CSA-certified testing ensure every part meets spec

Seamless Logistics

Cranes, forklifts, and truck-ready handling

Your Source for Consistent, High-Quality Manufacturing

We focus on building ongoing production relationships but remain fully equipped to support projects of any scale where collaboration and quality are priorities. Whether you require a large program or a specialized order, Metalumen is dedicated to delivering responsive service and reliable manufacturing solutions.

Videos

Paint Line Walkthrough

A step-by-step walkthrough of our paint line – following parts from beginning to end!

Sable Metal Enclosures

A behind-the-scenes look at the production of custom metal enclosures for Sable Metal Fabrication

Downloads

Our Core Capabilities line card is now available in PDF!

Let’s Build Something Together

Contact Martin Stocker today to explore how Metalumen can support your production goals with tailored, high-quality solutions.